After traveling in our RV for 2 years and 7 months through 39 states one of our biggest fears came to fruition. A slide on our 2019 Thor Challenger 37YT got stuck while we tried to set up in Fargo, North Dakota. We’ve heard the nightmares of Schwintek Slide System Issues, and it caught up to us.

As we started to put the slides out the first two went as normal then as we started to extend the third it moved out a couple of inches and I heard the rear motor bog down and stop.

I immediately stopped extending the slide and moved it back in. I tried extending it again with the same results. When I went out to see what was happening I noticed the front part of the slide was out about 3 inches but on the back where there was some binding the top was nearly all the way in still and the bottom out about 3 inches.

When I would retract the slide the front and top rear would close but the bottom stayed out the 3 inches. I couldn’t figure out why this would happen since the top and bottom are tied together with a driveshaft.

I looked into the manuals, online, and on YouTube for troubleshooting guidance but couldn’t find anything on if the slide was in on top and out on the bottom.

Luckily for us, the slide was nearly all the way in so we just left it as we were traveling daily for the next few days. When we got to Sioux Falls, South Dakota we stopped at Camping World to see if they could help. They were booked out longer than we were in town so they recommended a Mobile RV Technician. We called him and he came to take a look. He also was leery of working on the system because parts were so hard to come by. We decided to just leave the slide as is till we got to Texas where we had a three-week stay booked.

This post contains affiliate links. As a participant in Amazon Associates and various affiliate programs, we are compensated when qualifying purchases are made through our referral links at no additional cost to you. Full Disclosure

Schwintek Slide Systems

Over 70 RV brands use the Schwintek slide-out system from Lippert. A Schwintek slide is a type of slide-out that’s commonly used on motorhomes and towable RVs. The slide is unique in that it uses some worm gears to make the slide move in and out of the RV.

There are motors on either side of the slide that help the slide move when you want it to move, and there’s a panel inside the RV that allows you to control the motor. Schwintek slides are generally easy to use and that’s why you’ll find them on a wide variety of RVs out there.

Diagnosis

Once we got to our first stop at Lake Texoma Thousand Trails first thing we did was contact a couple of RV dealers to see if we could get our coach into the shop. Since it’s fall they both were booked solid till at least December with people getting their RVs winterized.

I started looking for a Mobile RV Technician. I got the name of one from one of the dealers I had called. I got one from the RV Park and one I found online. I called the first one and left a voicemail about my issue. The second had a full voicemail. I also sent each a text about our issues. The third technician I called actually answered and said he’d be over in 30 minutes to check out the coach.

He arrived and we tried putting the slide out. It jammed up as it had previously. He looked at it for a few minutes and told me that it would need to go to a shop since he couldn’t access the top motor from the outside and to get to the motor on the inside he’d have to take apart all the trim work around the slide. This technician told me no one would want to do the work in the field. He charged me $100 for a service call, I thought OK I guess it needs to go to a shop.

That evening I received texts back from the other two Mobile RV Technicians I decided I’d let them know that I had someone look at it already and I was told it needed to go to a shop. I responded back and one said OK, the other gave me a call and asked about our issue and who I had look at it. I told him who came out to take a look and what our issue was. He told me the technician that looked at it was a bit green and that the motorhome didn’t need to go to a shop to have it fixed and that he’d come to take a look.

Shawn arrived and we ran through the same opening procedures that I did the day before with the other technician. The slide still refused to open properly. Shawn then had me open the basement door to access the controller. He set the controller into manual mode and we got the slide to open fully.

I had read in the troubleshooting about the manual mode but didn’t fully understand how it would work with the slide cockeyed like ours was.

Once the slide was open we started to retract it but it made a bunch of noise and was really shaky closing so we extended it out so we can have our living space while we wait for parts. The top track had a lot of metal shavings where the gears were rubbing wrong.

After seeing how easily Shawn was able to get the jammed slide opened I was mad that I had been charged $100 for a “Mobile RV Technician” to tell me it needed to go to a shop. If the guy didn’t know how to use the manual procedures I don’t feel I should have been charged.

Parts

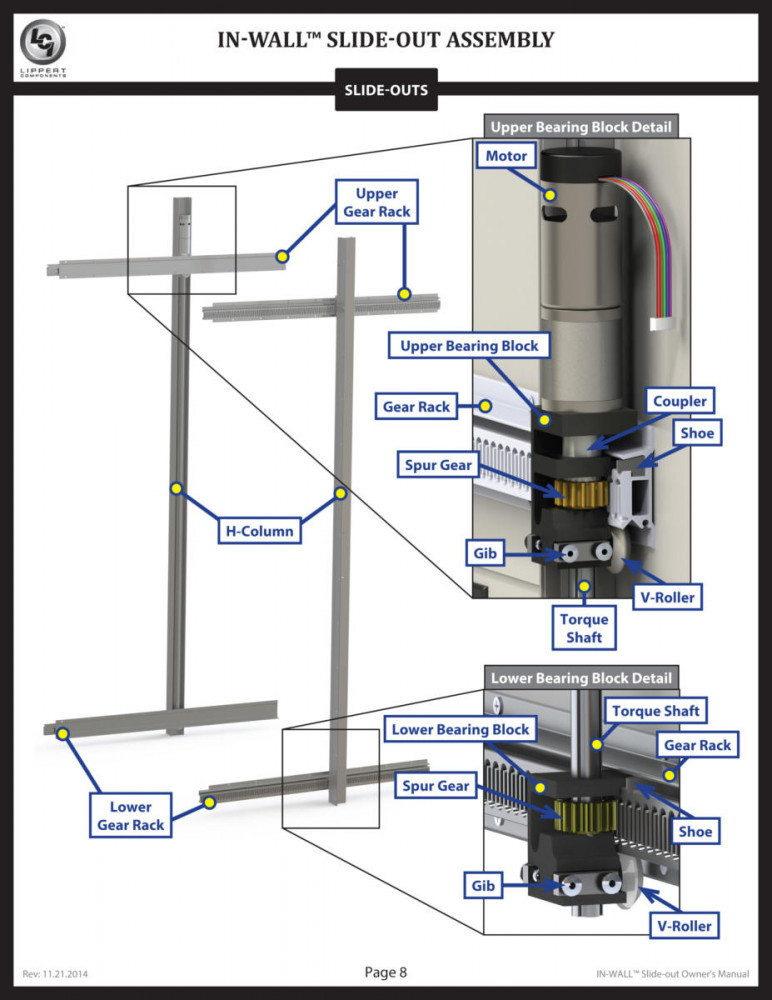

Shawn ordered the assembly that includes Upper and Lower Gear Racks, H-Column, Motor, Upper Bearing Block, Coupler, Shoes, Spur Gears, Torque Shafts, and Gibs. Pretty much everything is needed to replace the entire rear-track assembly.

Extended Warranty

Thankfully we paid for an extended warranty for our RV. This is the first big issue we’ve had with our motorhome so the extended warranty is going to save us from having to dip into our savings for this repair. The total cost for this repair was $1602. With our extended warranty we only had to pay the $200 deductible. So glad the warranty covered this repair!

Repair

Parts were ordered from Lippert on November 16, 2021. We hoped for a two-week turnaround but as of November 30th, they had not shipped. When Shawn called Lippert on November 30th they said if our order is in the next shipment they will go out on December 6th.

December 6th came and went with no response from Lippert. Shawn called and talked to them but they didn’t have any word on our parts shipping.

December 14th Shawn called and told me his card was charged for the parts so we guess they were on the way!

December 17th Shawn called to tell me that the parts were on his front step when he got home. Great news for us. He’ll do the installation on Monday or Tuesday.

When I got a look at the parts they were manufactured on December 8, 2021. Lippert is building the parts and sending them out as quickly as they can.

On December 21st Shawn and his helper, Jason showed up to swap the parts. There were a bunch of rivets that hold the H-Column to the motorhome. The first thing they did was drill out the rivets. Normally the H-Column will come right out after the screws/rivets are removed but of course, with our Thor Challenger, it lived up to its name of being a challenge.

Come to find out there are two brackets on the inside of the motorhome that need to have the screws removed before the H-Column will come out. Once we found that out it was a pretty straightforward swap.

The whole problem was the V-Roller had been damaged somehow in the operation of the slide. This caused the jamming of the slide and all our problems. There is so much weight on the V-Roller that it is no wonder it didn’t hold up. The slide that jammed has our residential refrigerator, kitchen, and dining area on it so it is very heavy.

Once everything was changed out we ran the slide and everything is now back to normal… For now! Praying we can make it to Tucson for our Vroom Slide System Upgrade without any more issues.

What’s Next?

Once our motorhome is fixed and the slides working as they should, we’re back to worrying if they’ll have another issue down the road. Knowing there are so many issues with the Schwintek Slide System, especially with the larger slides like on our coach we’re looking into other options.

Vroom Slide Systems is the only competitor for Schwintek. It’s a direct bolt-on replacement for the Schwintek System but much more robust with better motor attachment, bigger gears, and tracks. After calling and talking to Brian Vroom we’ve decided on having his system installed on our motorhome. The Vroom Slide System is not cheap coming in at about $2500 (as of November 2021) per slide. We feel the upgrade is worth it for the peace of mind it’ll bring with all of our travels. Just the repair of our slide on this issue came in at more than half that price.

Conclusion

Since our motorhome is our “home” we want the systems to always work when we go to use them. RV manufacturers build these things as cheaply as possible to keep their bottom line padded. The Schwintek Slides are a cool design and work well in smaller RVs with smaller slides. But when you get to a 17′ or larger wall slide with the whole kitchen and dining area it adds up to a lot of weight for the small motors, gears, rollers, and tracks. For these reasons, we are going to move forward with changing out the Schwintek System for the Vroom System come April 2022. Now that we’ve changed to the Vroom Slide System see how things went here.

Have you had issues with your slide system? What type of slide system do you have on your RV? Thank you for reading our article. If you have any comments or questions we’d love to hear from you below.

Back again!

I’m working on my 8th system since last post on Dec.30th, 2022- so, about 18 to date in a years time!! It’s a Forest River Cherokee Wolf Pup 17JG. I’ve had to rebuild these slide room systems on everything from 26′ Vibes to these small 17′ Pups. Had a conversation with a warranty rep. at Forest River and I was told they WILL NOT install anymore Schwintek In-Wall Gear Rack systems EVER again! Apparently, from 2020 – 2022, Forest River, fought long and hard with Lippert (Corporate Entity owner of Schwintek) because every system they’d installed were failed before trailers even left the plant!

Some common issues have revealed themselves in most of my rebuilds- the front H.Column Assembly is supposed to be the fixed position assembly, meaning: the bearing blocks are “fixed secured” in place inside the H. Column with rivets, to avoid any movement fore/aft at this section of the slide room. The rear H. Column Assembly is the floating position assembly, meaning: the bearing blocks are temporarily secured into the rear H.Column with plastic pins. These pins are meant to allow the bearing blocks to break loose inside the H. Column to allow necessary minimal movement fore/aft as the system extends/retracts, so as not to remail so tight as to jamb up the system. In most cases, it is the bearing block guide shoes and bearing blocks themselves getting damaged, galled, broken, and/or cockeyed in the gear rack guide tracks that causes the system to jam up. It is rarely an electrical issue, though the velocity controller will throw codes that are relative to electrical issues. When the system is jammed up, the controller senses the hall sensors on the motors amping out and is then forced to set some type of code, it doesn’t actually know it’s experiencing a mechanical issue.

What I’ve found and done to resolve:

Some of the room cutouts in the trailer are not trued up, and most are oversized. So if you get the clacking sound, it is because the floating position column was given too much room and the spur gear is making surface engagement with the gear rack due to the excessive space in the room cutout allowing the bearing blocks to float too far out of position. The last two units I’ve disassembled I found the front position H.Column configured as a floating position assembly, and I’ve also found the rivets used to secure the bearing blocks were not long enough to form a clamp on the bearing block/H.Column assembly. A couple of units I’d disassembled in which the front H.Column fell right off the bearing blocks! No rivets at all!!

So, I rebuild the H.Columns with the correct new parts, I double rivet the front upper and lower bearing blocks so they are truely “fixed” in position. In some cases I’ve had to hand machine a hardwood shim and epoxy in place to close up the gap in the vertical part of the opening. It’s not a simple process by any means! And warranty and extended service contracts are not accommodating much of this.

The steel torque rod shaft is a better design. The standard gear rack configuration is MUCH better than the inverted configuration, but one is not easily replaced with the other- mounting screw holes wont line up on the upper gear rack, and the height of the columns will differ. Used bearing blocks suffering any type of galling or damage CANNOT be reused. Neither can gear racks that show galling of the inside edge of the guide track.

It’s a terrible system, just sayin…

There is some decent documentation at Lippert regarding the slide room system; install instructions, parts identification, troubleshooting, etc. Really good information. You’ll have to go to support, slideots, documentation…. it’s all there. and it’s helpful, though for a useless system!

Hi Steven, Thank you for your input. I agree there are a lot of issues with the Schwintek Slide Systems. I had the Vroom Slide System put on my motorhome and have been very happy with that. Please feel free to put your contact information here for people to contact you to work on their systems if you like.

Rob

I have had two of my schwintech slides repaired 5 times each. The rivets on the gib pop and fail first- always the lower gib on the front side. Each time Grand Design replaces the H column on both sides of the slide- it last for about 5- 6 K miles and then breaks again. They have tried everything- measurements- complete removal and reset of slide, add rollers. etc etc. It is just a terrible design by Lippert and the Lippert refuses to redesign. 95% of all RV mfg use the same slide which is why Lippert does nothing. MFG tolerate it. Until another design comes up that is better and will sell to MFG s for the same price as Lippert- nothing will likely change. All I can say positive is that Grand Design has been faithful to repair at no charge. I follow all the rules, recommendations etc- I am a slow driver 55mph… and watch for bad roads. I am not sure there is a solution . VROOM is now price gouging with an 80% increase in their bolt on system- almost $5K per slide now!

Sorry to hear you have had issues with your Schwintek Slide System. It’s the nature of their system. The Vroom System is by far superior to the Schwintek System. I don’t think Vroom is price gouging since if you go to get a replacement Schwintek System you are going to be out nearly as much as the Vroom System.

Rob,

Great write up man. Even my colleagues have no idea how to resolve the issues with the Schwintek system! Your experience and others like it confirm what I have come to believe through my experience working on these systems. The design is not very well executed. I am anticipating reports from the Vroom system users.

Thank you so much for the kind words, Steven! We’ve had our Vroom Slide System for about 9 months now. So far so good. There hasn’t been a single time where I thought the slide wasn’t going to come in or go out as it should. We’re very happy with the system. Here is our post about it. https://gofulltimerving.com/vroom-slide-system-upgrade/

Our contribution to the Schwintek Issues conversation…..just last March ’22 we bought a new Keystone Springdale Mini 1860ss from CampingWorld (CW) Avondale, near us in Phoenix AZ. We love the floorplan with the superslide. Took it out for a weekend in the summer and everything seems to work. However, just before Thanksgiving, the slide began to get stuck and wouldn’t extend without getting out of alignment. The rear lower corner hangs up and doesn’t go out while the other three corners go out….I stopped at about two inches when it was clearly out of alignment and then retracted it.

Problem is that with the slide retracted, I can’t get at the motor retainer screw to allow disengagement of the motor. In addition, the floor plan for this model has cabinets at the rear that are right up to the rear trim for the slide…..no way to get at the rear H-Column access panels to get at the motor or the drive assembly. We contacted CW where we bought the trailer and they are also heavily scheduled as it seems all are. I’m a little concerned that CW is going to have a difficult time getting at this part of the slide system. I feel that Keystone might have overlooked a few things with this design / build. They should have considered the vulnerabilities using the Schwintek knowing that it’s marginally adequate for larger slides and also that access to the “in-wall drive” components should have been factored into the build. My saga continues……

Hi Gary, Sorry to hear about the issues you’re having with the Schwintek System. I understand what you’re saying about access to the components. A couple of ours are very tight too. But once the trim is removed it is doable. Best of luck with yours. Rob

You are exactly right regarding manufacturer’s build decisions!!!… The Schwintek system itself is the issue right off the bat, poor execution and very light weight.

WE HAVE A 2022 TIFFIN WAYFARER 25RW WHICH HAS THE TWO THEATHER SEATS AND THE MURPHY BED IN THE SLIDE. OUR FIRST LONG TRIP AND THE SLIDE FAILED IN THE BLACK HILLS OF SOUTH DAKOTA. AS THE MURHPY BED IS IN THE SLIDE, WE COULD NOT SLEEP IN THE MOTORHOME. HIGH TAILED IT HOME TO PORTLAND OREGON. HAD TO TAKE THE RV TO A DEALER 200 MILES AWAY FOR THEM TO WORK ON IT. GOING TO REPLACE THE Schwintek IN THE REAR UNDER WARRANTY. WE PLAN TO INSTALL A VROOM SYSTEM IF IT IS AVAILABLE IN THE WINTER ON A TRIP TO AZ. ANYONE ELSE IN A CLASS C OR TIFFIN WAYFARER HAVE SIMILAR PROBLEMS?

Thank you for your comments, Jerry. Sorry to hear about the problems with your Schwintek System, it seems all too common. Plan well in advance for your Vroom upgrade. Give them a call and get scheduled as soon as possible. They are booked out a long way from what I hear. Best of luck with your coach.

Hey Rob, sorry y’all had to go thru that. I couldn’t tell from the post though, did you originally have the 3 track schwintech on ur slide or just the two rail model ? Thanks.

Hello Dan, Thank you for your comments. Originally we had the regular 2-track Schwintek System. Vroom does replace the 3-track systems also.

Has anyone had a problem with the Vroom slide system?

Hi Andy, I have not heard of anyone having any problems with the Vroom Slide System. I know Vroom tested their system over 6000 cycles with 1500 lbs of ballast on their mock up without any issues. I think it is a sound system and much better performance than the Schwintek System. Thank you for your question. Rob

I’m a moble rv tech and unless it’s a small bedroom slide, you are going to have problems. I have called Vroom and we spoke for quite awhile and saw a couple of videos from their customers. It is a tad pricey but… so much better.

Hi Lynn, thank you for your comments. I agree that Schwintek probably works ok for smaller slides but large 16+ foot slides found on some RVs are just too big for their system. We’re really happy with our Vroom System so far. We haven’t had to pray they are going to work yet. That’s worth a lot!

We have a 2022 Grand Design Imagine 2670MK which has the Schwintek system on a larger slide room (contains the kitchen a large countertop, and the TV with lift). It was first replaced by the dealer we bought it from in November of 2021 during their pre-delivery QA check. We took delivery in February of 2022, went camping 1 night on the way back (we live in Nevada and bought in Arizona so wanted to stay close just in case anything went bump). We later went camping for 3 nights (boondock), the slide was making some grinding noises and popping. Never having had this system before, I assumed it was normal because it had done it every time. Well, after loading up for our 3rd trip, the exact situation you describe above happened to us. We were told it was impossible for the top to be out further than the bottom, or vice-versa… I said well, here’s a photo. Long story short, we took it to Blue Dog in Las Vegas, and they said the system needs to be replaced again. Talking with Grand Design, they’re telling us the system has been re-designed because of those issues, and the system we’re getting is the new design. It is currently on it’s way to the dealer, but I’m just worried about it still. I’m considering the Vroom system that I found out about through other sources, but they cite the same things you do about it. Thank you for this article, it has been hard to find anyone else with this same issue.

Hi David, Thank you for your comments. I totally understand the frustrations. I’m fairly mechanically inclined and I couldn’t figure out how the bottom ended up being out further than the top since everything is tied together. I couldn’t find any information from others that had the same problem. We’re very happy with the Vroom System so far. We’ve had no problems with it. I hope Grand Design gets your RV fixed to your satisfaction. Best Wishes, Rob

We also have a 2018 grand design 2670mk. Our kitchen slide has never been right. Grand design nor lazy days has provided any satisfaction. Lazy days did a horrible repair job and left us with more damage than they fixed. None of the extended warranties paid up. Our sub floor now has a rut being worn in the bottom of it. I have to shove the back of our slide to get it to close up every time. I hope you have better luck with yours. Also if they put those westlake china bomb tires on yours, replace them a.s.a.p.

Thank you for your comments, Tommy. Sorry to hear of the issues you’re having with your trailer. It seems that when the dealers do the repairs on the Schwintek Systems they are only putting on a band aid and the problems will come back shortly after. We’re very pleased with the Vroom Slide System. Things seem to run so much better. Thankfully since ours is a Class A motorhome they don’t use cheap tires on them. Hope you can get yours running well soon.

Rob

Hey Rob and David,

I’m at RV tech up here in Alaska. Dealing with these same issues currently!

The Lippert Schwintek system is a weak design. I’ve had several apart several times and the build of this system will not support the weight of the slide room, they are all going to fail, without a doubt.

If you’ve gotten acquainted with your system, you’ll have found that the room carries on the upper and lower spur gears encased in a gear box that ride along the gear racks. Directly beneath the room, it sits atop 2 or more support floor rollers that are installed directly in/onto the wall sill beneath. The room basically glides along this section of the sill, teeter-tottering in real world effect (which is what is binding up the system) as the spur gears attempt to move the room in/out via the gear racks (that are attached directly to the wall sides). When weight moves forward over a cantilever it is going to want to fall to that direction, especially with no more further support. If the room were balanced on that lower wall it would sit there supported, once it moves more to one side of the cantilever, it is going to fall to that direction. You have to have noticed that right before your systems have bound up, the room is tipping coming in or going our once it reaches a certain point of its travel. The only attempting to keep that room straight while retracting/extracting, are the upper and lower gear blocks on each side of the room. All parts are light weight aluminum, the gear blocks do not fit tightly into the H-Columns (this is the trim portion screwed to the exterior side wall holding everything in its place, or at least intending to) so something had to occur when the weight shifts… think about it. The gear blocks and spur gears are being demanded more of than they can accomplish. Everyone, every time, going to happen, sure thing. It’s a poor design for a viable amenity, and it is a weight support issue.

Thank you for the great input, Steven! You confirm exactly what I have thought about the Schwintek System. Our slides worked perfectly until the time they didn’t. As soon as our big slide jammed I knew that we would have continuous problems with the Schwintek System. It was a hold-your-breath-and-pray situation every time we moved the slides in or out. I agree it is a poorly designed system.

We have an issue with our schwintek slide in our Challenger, but a different problem. The slide is not the heavy slide but the couch slide behind the drivers seat. The slide goes in and out with no problem, but when driving the top to the slide behind the drivers seat grinds/rattles (I think it is moving a little also, but cannot tell when driving). I am assuming there is a problem with the motor/gear mechanism on that end of the slide. The rack does not show any wear or broken teeth. From your write-up, it appears (and I hope) the motor/gear system can be removed without removing the slide. Where can I get more detailed prints/pictures of the unit and possibly how to remove it. We have a 2-16 Challenger 37GT. Thanks in advance!

Hi Steve,

Thank you for your question. Yes, the motor and gear system can be removed without removing the slide. You might first check to make sure the motor isn’t just bouncing around. They are only held on by a single set screw on the Schwintek System. So if it has fallen out or is loose the motor is free to do whatever it wants to. For detailed prints/pictures contact Thor directly. They are usually very helpful. Also, check out any YouTube Videos on Schwintek Slide Systems you can find quite a few online. Best of luck with your slides.

Rob

My wife and I used our life savings to purchase A 2020 Allegro RV, from Camper’s Inn in Raleigh. It has been over two years and we have not made a single camping trip, that the main slideout has worked. Our plans to travel and connect with friends have been replaced with two years of frustration and anger.

TIMELINE

1. Purchased 2020 Tiffin Allegro February of 2020

2. Did not receive tag and title until January 2021

3. Using temporary tag, made first camping trip November 2020

4. Noted warranty items for repair, Schwintek Slide Out being biggest concern

5. Our Allegro spent over 7 months at Campers Inn in Raleigh before repairs were completed and Swintek Slideout was replaced (Jan. To Aug. 2021)

6. November 2021, we took our next camping trip and again wintek Slideout would not work

7. December 2021, we took our Allegro to Campers Inn in Mocksville, Swintek Slideout replaced again. Slideout trim not painted, because of weather it was March of 2022 before Allegro was painted

8. April 2022, we took our next camping trip and again Schwintek Slide Out would not work

9. April 2022, notified that warranty would not cover installing a fourth Slide Out

We have logged over 1,500 miles on our Allegro and 3,000 miles on our personal vehicle, driving back and forth to Campers Inn.

Hi Jim,

So sorry to hear about your frustrations with your RV and particularly your Schwintek Slide System. I think if it was me I would go directly to Tiffin in Red Bay Alabama to have them find out why the Schwintek System isn’t working and/or have it replaced with the Vroom System. They have a technician that has been trained on the Vroom Slide System there. It might be beneficial to contact them. We’re full time and very leery of taking our rig to the dealership for any repairs. We took ours in the first year before our warranty was up and they wanted to keep it for a week. I said no way! Again sorry to hear of your troubles. Best of luck with your coach!

Rob

I’m having a slide problem as well on a new 2021 unit.

It’s currently in a shop that I trust, and one the Tiffin works with. Do you know if Vroom sends their replacement systems out to approved shops, or do you have to take it to Tuson for repairs?

Hi Gary, Thanks for your questions. Vroom has started training people to do the installations in locations other than Tucson. They have trained some people for Tiffin in Red Bay, Alabama. I think they also have someone trained in Connecticut and Texas but not sure exactly where. Let me know if you have any other questions. Good luck with your slides.

Rob

Hi Rob

Your article just sold me on Vroom and was just what I have been searching for. Great details!!

Thanks.

Gene

Thank you, Gene, Our coach is in the shop right now getting the Vroom Upgrade. I’ve been impressed when I’ve stopped by the last two days to see what the guys are doing. Joey the team manager is very knowledgeable and showed me all the parts and explained them to me. We should be getting our motorhome back tomorrow and in the next week or so I’ll be writing up an article about our experience at Vroom. Good luck with your systems.

Rob

Schwintek slides are inherently defective.

Manufacturers and Dealers alike know it. It is an industry wide problem.

They knowingly sell Rv ‘s with defective slides.

They r interested in sales first and then wait to try to repair.

Each owner thinks it is just their coach.

Manufacturers put them on

because they r cheap.

We r being scammed.

I wouldn’t say they are inherently defective. I would say that they are not robust enough for large slides on Class A motorhomes. I think they probably do well on smaller slides on travel trailers and Class C motorhomes. They are cheap and actually easy to work on. But for big Class A slides with lots of weight on them I think the Vroom System is going to be a much better system. Even Tiffin is starting to put them on their new Class A’s.

They fail on most everything, I work in the field. Four in front of me right now, little 17′ Wolf pups, small rooms. Once these things leave the factory, and go bouncing down the road, they are going to fail. Every last one of them without a doubt. They are not robust enough to carry and manage the weight of the rooms they are installed on, and the assembly of the mechanical parts is very light weight.

Hi Steven, Thanks for your comments. I never knew the smaller slides were having the same issues as the bigger slides with the Schwintek System. That’s sad to hear. I can understand why they wouldn’t work with the larger slides but to not work with the smaller slides too is really troubling.

Hi Rob, I just found your article after a search on Vroom systems. Are you still planning on getting this installed? I have replaced one side of my Schwintek triple track system, and it is already making grinding noises again, so Vroom may be in my future. Any details on the install and overall function after install would be great. Thanks!

Hi Mike, Thank you for your question. I actually just talked to Brian Vroom this morning to confirm our appointment to have the Vroom System installed on our coach on April 4th. We changed the one H-Column and Gear Racks on one of our big slides, and also have noise coming from the same area again. We just keep praying we can make it to Tucson to get the upgrade. I think for any Class A large slides the Vroom System is going to be the way to go. I plan on doing a write-up on our experience and how the system works when we’re done getting it. I’m going to see if they’ll let me shadow them a bit and get some video of the change out. Good Luck with your slides. I’ll keep you posted on what happens with ours.

Rob

Hi Rob and Lisa!

Thanks for such a detailed write-up about your experience with your slide. We’re dealing with a slide issue ourselves. I was wondering what the RB tech put on the report that was sent to your warranty company. Cornerstone denied our claim because they said the issue wasn’t mechanical.

Thanks for your help!

Hi Roy, Thank you for your question about our slide. What is the problem with your slide if it’s not mechanical? I believe the Mobile Tech put that our H-column and gear rack were bad. This got us the whole assembly. The actual problem was the top V-roller had partially come off the wheel and jammed things up. Good luck with getting your slide fixed.

Rob